Particle size: < 50 nm

Solid content: 25~28 wt%

Viscosity: 2~8 mPa · s(25℃)

Surface tension: 78~93 mN·m-1 (25℃)

pH: < 4

Stability: 24 months (0 ~ 40℃)

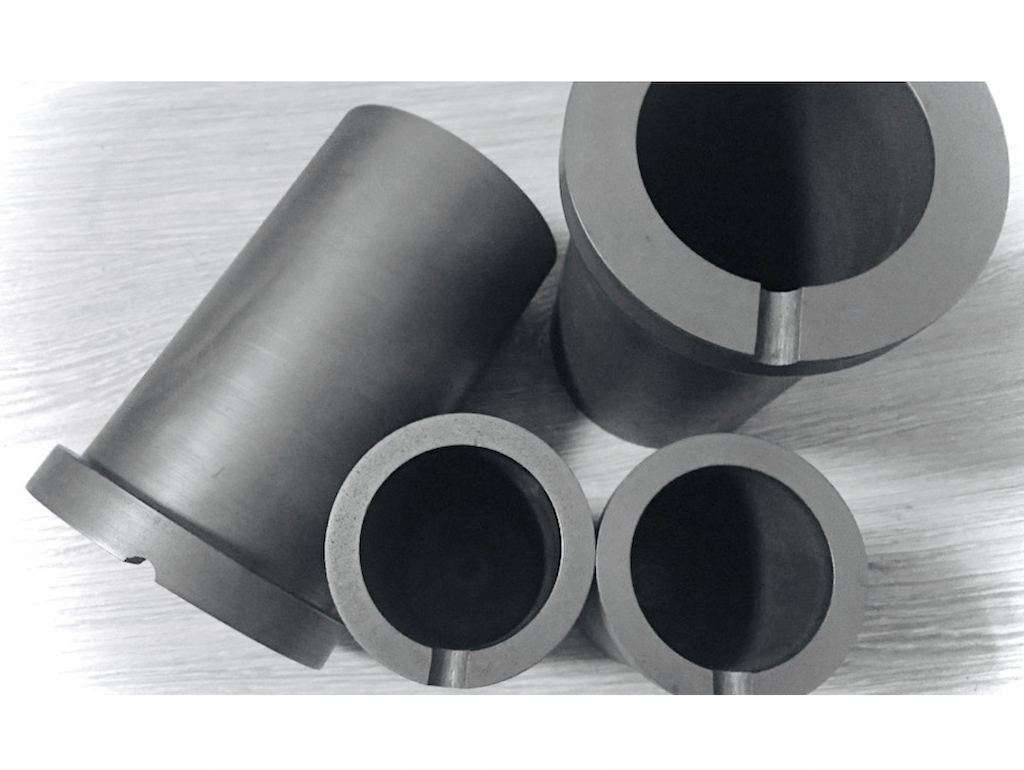

“Graphite Crucible Impregnation-Type Protective Agent (C•CPM-03)” is a multi-component water-based colloidal solution by adjusting the ratio of zirconia (ZrO2) to oxide on the basis of “Impregnation-Type protective agent used for graphite electrode" .

Micro/nano technology preparation, no VOC organic emissions, environmentally friendly;

“Graphite Crucible Impregnation-Type Protective Agent (C•CPM-03)” is used to prolong the lifespan of graphite crucible and graphite ejection plate for the production of nitrogen-carbonized vanadium in tunnel kiln. It is also used to reduce the consumption of graphite crucible for smelting copper alloy in induction furnace and graphite stirring rotor for aluminum melting furnace.

The Graphite Crucible Impregnation-Type Protective Agent (C• CPM-03) is dipped into the micropores of graphite crucible to block the open pores, reduce the corrosion of sodium oxide, potassium oxide, vanadium oxide and other corrosive gases in the production process of nitrogen-carbonized vanadium, and prolong the service life of graphite crucible.

Sweep, pay attention to us